Separation layer detection in the pipeline for batch separation

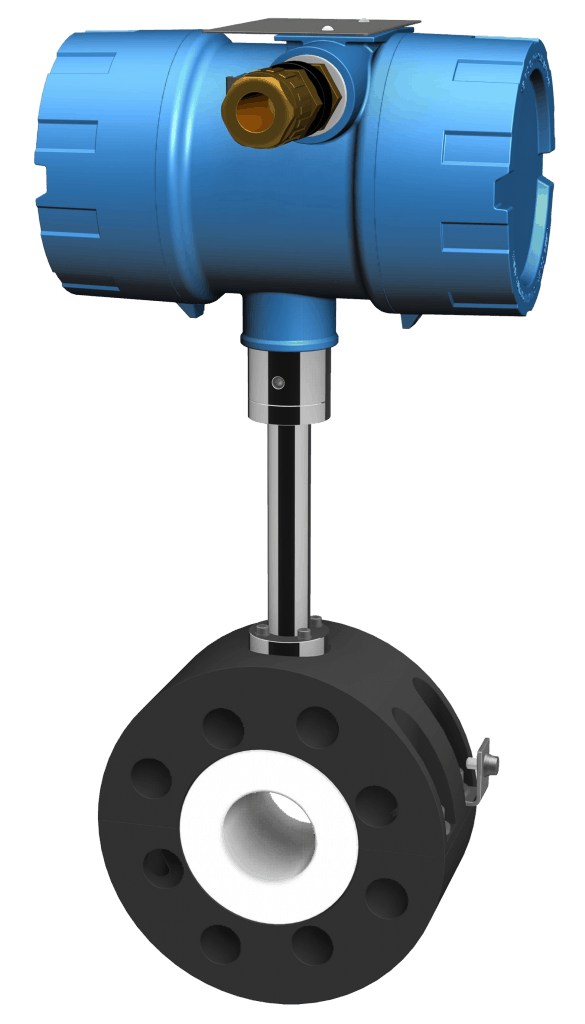

Fully-automatic phase separation without requiring commissioning for batch production in mono or multi-purpose systems saves time and costs. The plug & process separation layer measurement of non-mixable fluids is performed using TSS80 tube probes after the outlet valve. Emulsion layers, phase reversal or conductive organic phases, severe contamination or the tiniest density differences can be recorded automatically, quickly and reliably and separated in batches with the dynamic measurement value monitoring system.

Customers tell us about interface detection with TSS80 ring probes:

... «Emulsion layers, phase inversion or conductive organic phases during phase separation, heavy contamination or the smallest differences in density are automatically, quickly and reliably recorded with the dynamic measurement monitoring. With the interface detection, the phases are separated exactly in batches. »mipromex – the multi-talent

The separation layer unit monitors, detects and controls the separation

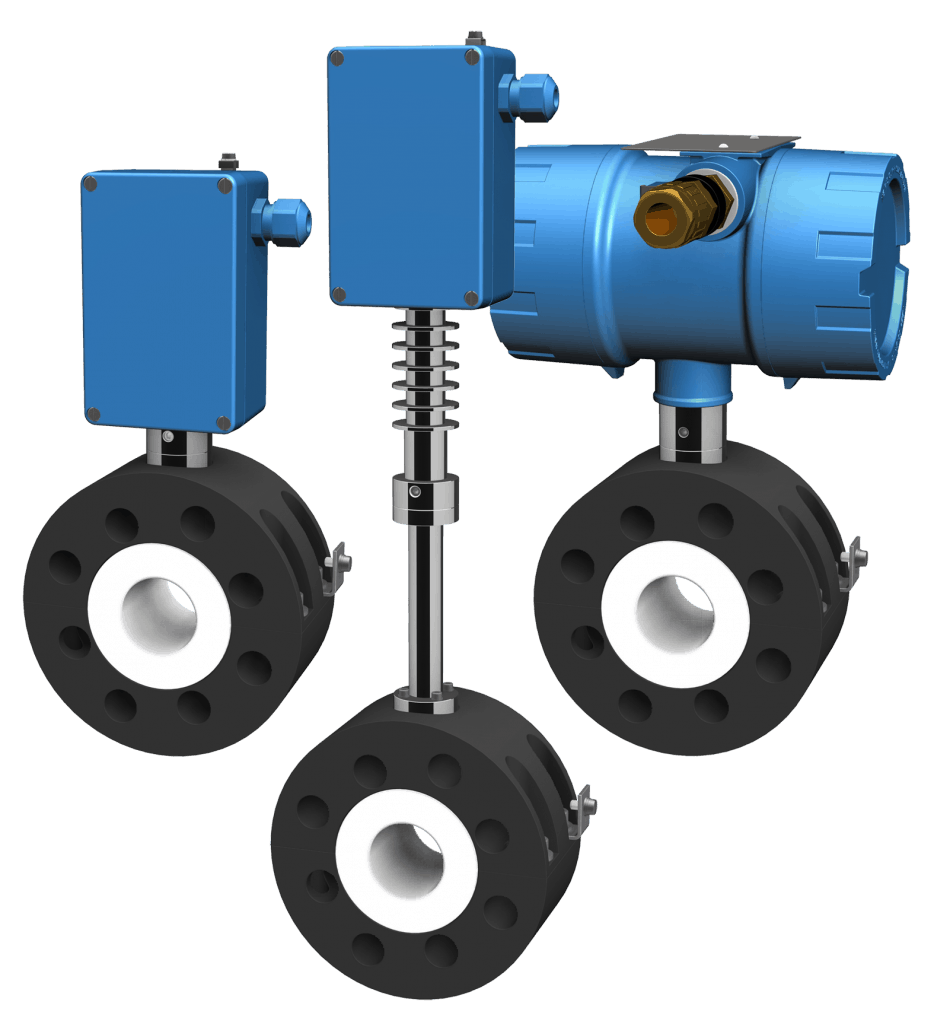

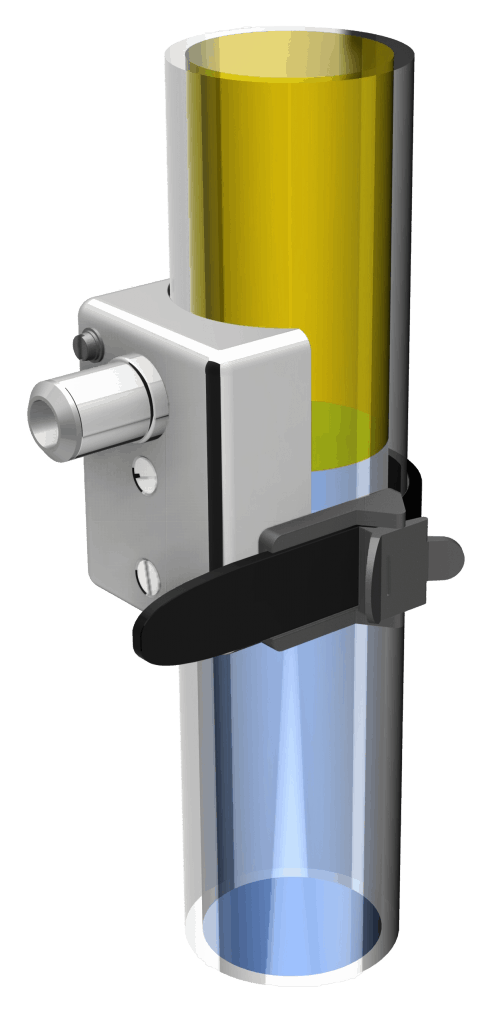

The high-resolution measuring system detects the separation layer fully automatically in the pipeline. The MIQ separation layer measurement unit with the TSS80 ring probe monitors the phase separation in batches in the pipeline (full PTFE design with a free outlet). Our customers are impressed by the universal use, high measurement precision and easy commissioning. A reliable measurement of all products is guaranteed by applying the impedance measuring principle with hysteresis activation. With separation layer tube probes of various nominal diameters, it is possible to measure the separation layer directly in the reactor or separation vessel outlet. The self-monitoring measuring and control unit ensures reliable fully-automatic separation.

Fluid/fluid phase separation

Customers therefore rely on aquasant® batch interface measurement

- No commissioning required, plug & process

- Fully-automatic phase detection

- Rapid measurement signal

- Density independence

- Separation layer measurement of two organic phases

- Measurement through glass instruments without touching the product

- Measurement without sensitivity to contamination

Measuring system

The standard TSS80 tube probes are configured based on the customer-specific process conditions. The full PTFE body can withstand aggressive media. Plug & process, the TSS ring probe is parameterised and does not require commissioning.

- Nominal diameters: DN 32/40, 50, 80, 100 PN16 and ANSI 2, 3, 4" 150 lbs

- Standard temperature 80° C, with cooling element up to 170° C

- For insulated lines with extension for detached connection head and/or with a cooling element for product temperatures of up to 170° C

- Connection head for indoor IP65 or outdoor IP68 in Exd

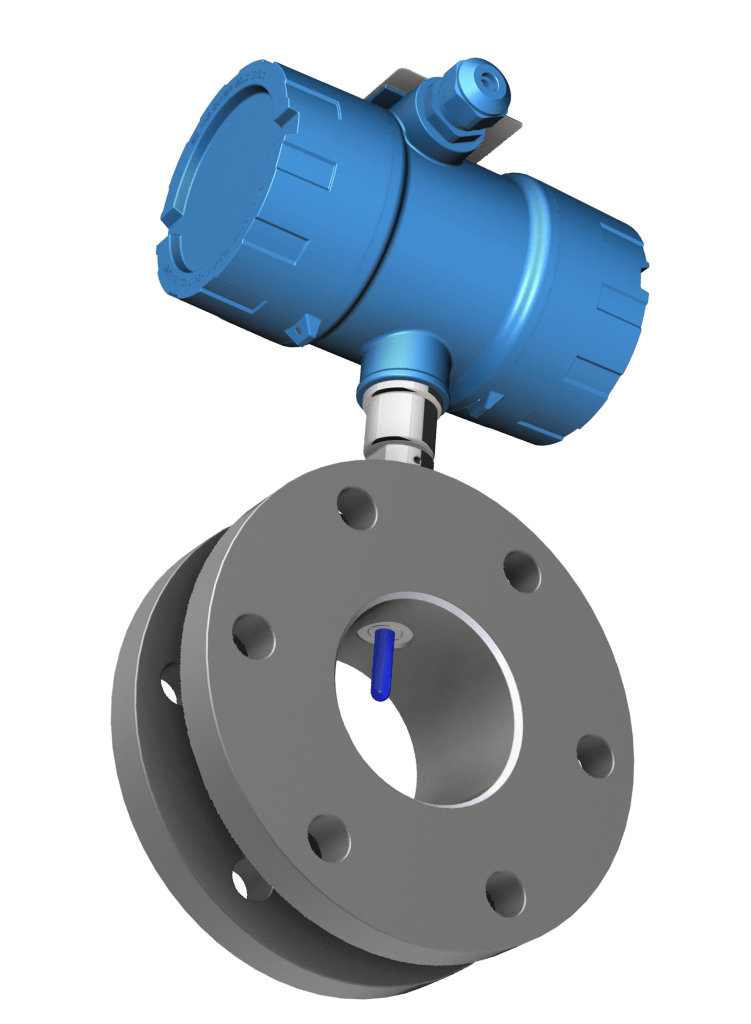

The standardised bar probes are configured to customer-specific process conditions and the media used. In contrast to the floater system the probe technology is density-independent and maintenance-free.

- Materialisation: Stainless steel 316L, Hastelloy C22, full PTFE designs

- Contamination in the inactive area and organic residues on the measuring electrode are negligible

- Designs for extreme process conditions with temperatures of up to max. 300°C and pressure up to 1000 bar

- Despite the top aqueous phase (phase reversal), we achieve precise measurement results

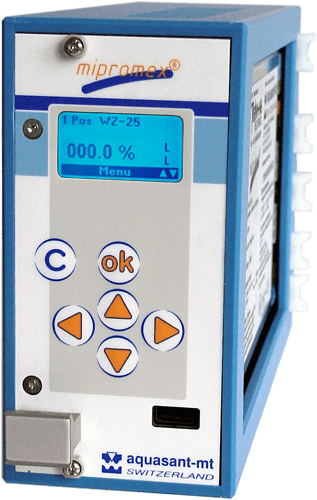

The multi-talented MIQ can be used from batch separation to the separation layer level measurement. The second measurement circuit can be used for the phase monitoring system, the fill level or the separation behaviour. The evaluation electronics not only serves as a feed unit in the 2-wire technology, it also houses the data processing intelligence. Your benefit: High economic efficiency and investment security due to the long service life.

Ex version: Gas II (2) G [Ex ia Gb] IIC EMC STS 024 CE ****

Further information on MIQ»

- Universally usable, reduced storage costs

- Easy fault visualisation, fault notifications on analog output

- With 1 or 2 measuring inputs

- mA output and limit value simulation

- Fully-automatic batch separation of the separating layer in the stirrer tank, decanter, reactor

- Continuous separation layer monitoring in a decanter, separation vessel, mixer-settler

- Separation layer detection with separation behaviour for time and quantity-optimised separation

- Continuous separation layer recording with product compensation of a phase

- Combination of continuous separation layer recording with level measuring of the upper phase

Ex version: Gas II (2) G [Ex ia Gb] IIC EMC STS 024 CE ****

Further information on MIQ»

Documentation

Batch separation of two fluid phases with the digital sight glass with the mipromex MIQ

Reliable phase detection of two non-mixable fluids directly in the pipeline with the TSS80 separation layer tube probes.

The automation of the separation of two non-mixable fluids after a batch process can be performed using the new dynamic measurement signal evaluation without knowledge of product measurement values, without commissioning and without limit value settings. The new measurement signal process provides a high level of functional safety even during the first separation and saves time and money.

Tech Docs: Interface pipe probe type TSS80

Tech Docs: Interface clamp probe on glass tube type FRGL80/60 SE R U EF GR60

Tech Docs: Interface evaluation unit type MIQ

Reliable phase detection of two non-mixable fluids directly in the pipeline with the TSS80 separation layer tube probes.

The automation of the separation of two non-mixable fluids after a batch process can be performed using the new dynamic measurement signal evaluation without knowledge of product measurement values, without commissioning and without limit value settings. The new measurement signal process provides a high level of functional safety even during the first separation and saves time and money.

PDF download

Brochure: Interface detection for batch separationTech Docs: Interface pipe probe type TSS80

Tech Docs: Interface clamp probe on glass tube type FRGL80/60 SE R U EF GR60

Tech Docs: Interface evaluation unit type MIQ