OWD Watercut meter for product monitoring in storage tank, oil/water detection

In petrochemistry, in particular in storage tanks, the potential for reducing the operating costs must be fully exhausted. When draining the tank, to protect the environment and prevent losses, the degree of automation must be maintained at a high level.

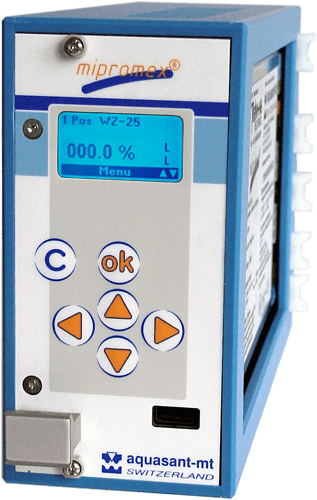

mipromex – the detector

The analog evaluation unit for use in the harsh conditions in the petrochemical industry with the TSS90 tube probe.

Using the TSS90 tube probe for automatically stripping the water in storage tanks saves enormous operating costs. The stripping process can be controlled via the analog signal in the process control system or directly via the internal limit value. The high-resolution tube probe can even detect small quantities of petrochemical products on the periphery.Safety for clean water, for the environment’s sake.

Rain water from floating roofs in petrochemical tank warehouses is conducted through the tank directly in moving pipelines. At the tank outlet, the pipeline is used with a TSS90 tube probe in the siphon. This way, the rain water is monitored for oil penetration or leaks.

Fluid/fluid phase separation

Why customers rely on the aquasant® OWD watercut probes

- No commissioning required, plug & process

- Rapid measurement signal

- Density independence

- Free pipe outlet

- Water monitoring of floating roofs in petrochemical storage tanks

- Monitoring of petrochemical products on water when unloading

- Automatic stripping of water in petrochemical storage tanks

- Measurement without sensitivity to contamination

- Cost-effective installation

Measuring system

The generalist, MAT, can be used from level measurement to monitoring system and detection. The first and second measurement circuits are equipped with the same functionality. The evaluation electronics not only serves as a feed unit in the 2-wire technology, it also houses the data processing intelligence.

Your benefit: High economic efficiency and investment security due to the long service life.

Ex version: Gas II (2) G [Ex ia Gb] IIC EMC STS 024 CE ****

More information on analog transmitter unit MAT4110 »

Your benefit: High economic efficiency and investment security due to the long service life.

- Universally usable, reduced storage costs

- With 1 or 2 measuring inputs

- mA output and limit value simulation

- Discharge rain water in petrochemical storage tanks

- Phase detection with separation behaviour for time and quantity-optimised separation

Ex version: Gas II (2) G [Ex ia Gb] IIC EMC STS 024 CE ****

More information on analog transmitter unit MAT4110 »

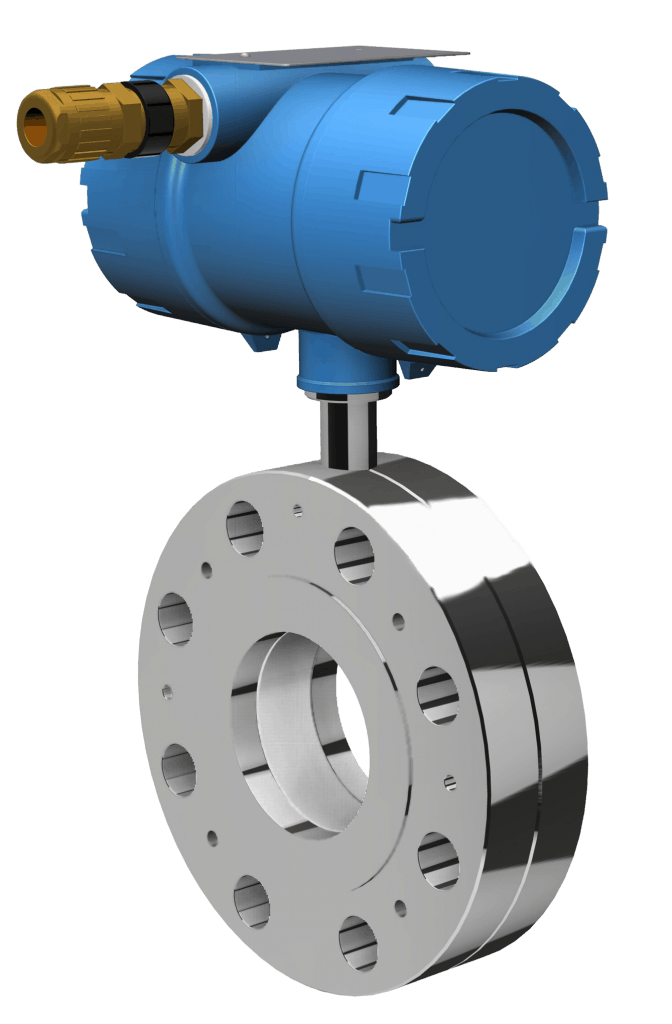

The standard TSS90 tube probes for OWD watercut are configured based on the customer-specific process conditions. The PTFE body held in a standard flange, is resistant. A high measurement differential guarantees reliable separation.

- Nominal diameters: DN 50, 80, 100, 150 PN16/40 and ANSI 2, 3, 4, 6" 150 or 300 lbs

- Standard temperature 80° C, with cooling element up to 170° C

- For insulated lines with extension for detached connection head and/or with a cooling element for product temperatures of up to 170° C

- Connection head for indoor IP65 or outdoor IP68 in Exd

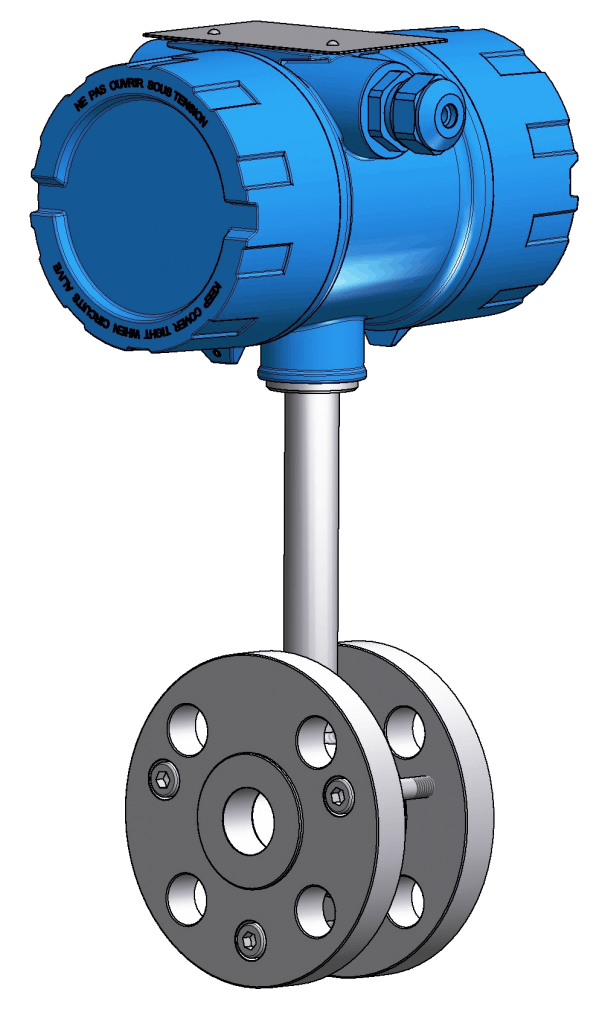

The special TSS100 tube probes with small nominal diameters are configured based on the customer-specific process conditions. The PTFE body held in a standard flange, is resistant. A high measurement differential guarantees reliable separation.

- Nominal diameters: DN 15, 20, 25 PN16, and ANSI 1/2,1" 150 lbs

- Standard temperature 80° C, with cooling element up to 170° C

- For insulated lines with extension for detached connection head and/or with a cooling element for product temperatures of up to 170° C

- Connection head for indoor IP65 or outdoor IP68 in Exd

Documentation

The automation of the separation of two non-mixable fluids can be performed with easy commissioning and limit value settings using the analog transmitter. The measurement signal process provides a high level of functional safety even during the first separation, saves time and secures investment costs.

Tech Docs: Detections pipe probe type TSS90

Tech Docs: Universal evaluation unit type: MAT

PDF download

Brochure: Phase detection for water separationTech Docs: Detections pipe probe type TSS90

Tech Docs: Universal evaluation unit type: MAT