SQV® tubing pinch valve used for bottling installations

Dosing in sterile zones, precisely controlled in feed vessel

For pharmaceutical bottling installations, our SQV® are used under sterile conditions in accordance with GMP. They interrupt the flow between the overpressurised and the unpressurised feed vessel without media contact

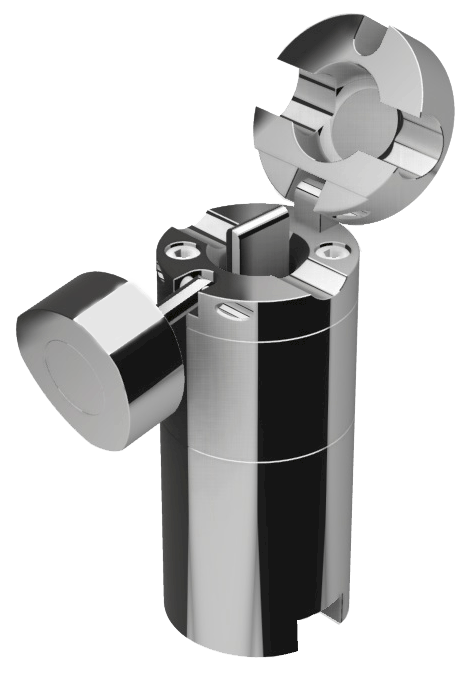

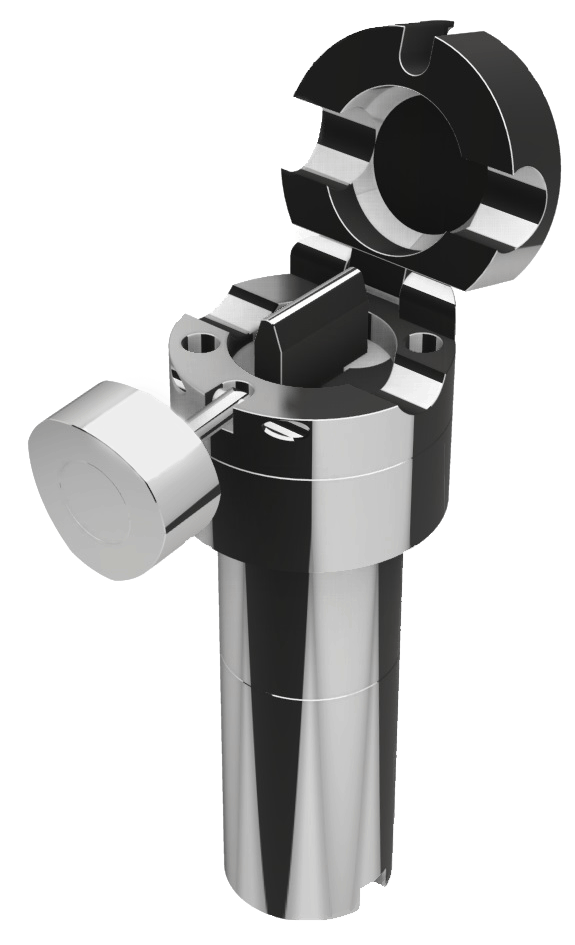

The SQV® tubing pinch valves are produced in aluminium or stainless steel as needed and depending on their use. The pneumatically operated aquasant® valves squeeze the silicone tubing gently enough that at least 10,000 switching cycles with the same hose are possible. Series 1*, 2* and 3*, manufactured from stainless steel, are characterised by an easy-to-use hinged lid

Tubing pinch valve type: SQV 84/20

SQV versions

- SQV® 83/15

- SQV® 84/20

- SQV® 96/2x11 MV

- SQV® 1* G1/8 VAe N KV

- SQV® 2* G1/8 VAe N KV

- SQV® 3* G1/8 VAe N KV

- SQV® 4* G1/8 VAe N KV

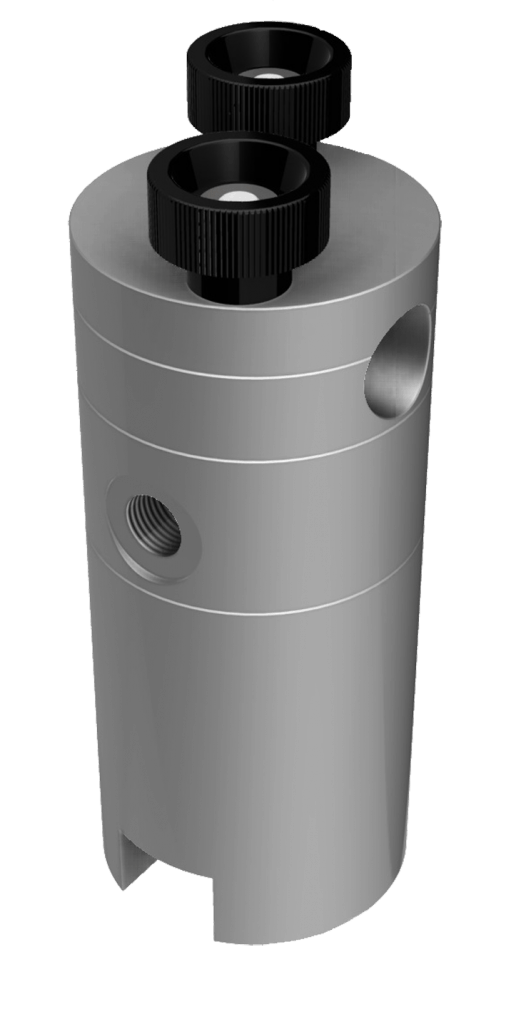

This reliable third-generation aluminium valve originated from customer needs. The hose squeezing valve’s essential features may be simple, but its high-quality workmanship is impressive.

- Use in sterile zone C/D

- Easy to handle

- Silicone tubing Ø 15.0 ±0.5mm, wall 3.0 ±0.5mm

- Standard: peroxide-cured silicone hoses Shore 60° ±5 (others on request)

- Insertion of hose by loosening two knurled nuts

- Min. 10,000 switching cycles with same silicone hose, without damage to hose

- Compressed air supply 4 - 6 bar

- Squeezing stamp in stainless steel

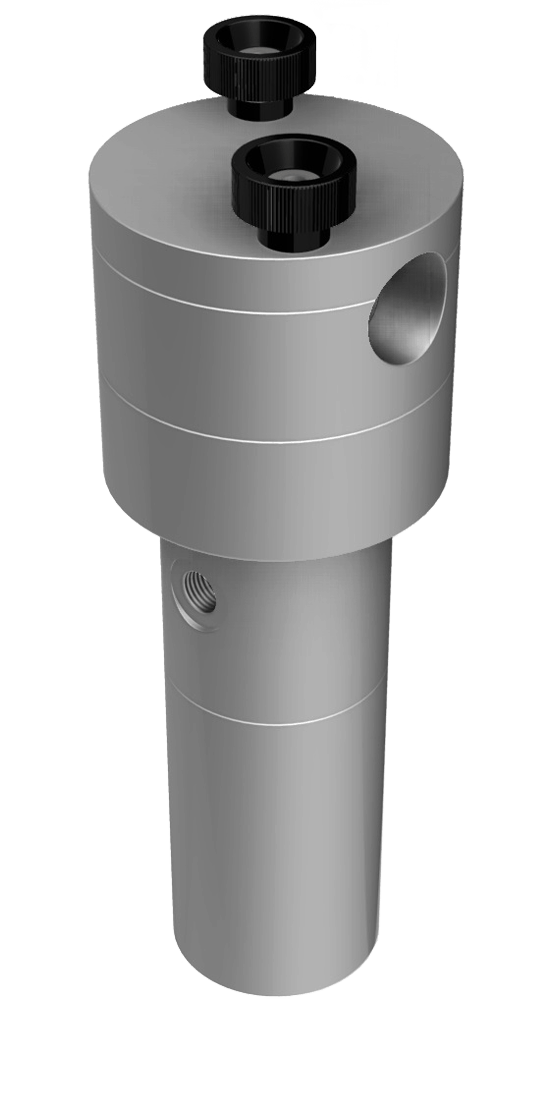

This reliable third-generation aluminium valve originated from customer needs. The hose squeezing valve’s essential features may be simple, but its high-quality workmanship is impressive.

- Use in sterile zone C/D

- Easy to handle

- Silicone tubing Ø 20 ±0.5mm, wall 2.5 ±0.5mm

- Standard: peroxide-cured silicone hoses Shore 60° ±5 (others on request)

- Insertion of hose by loosening two knurled nuts

- Min. 10,000 switching cycles with same silicone hose, without damage to hose

- Compressed air supply 4 - 6 bar

- Squeezing stamp in stainless steel

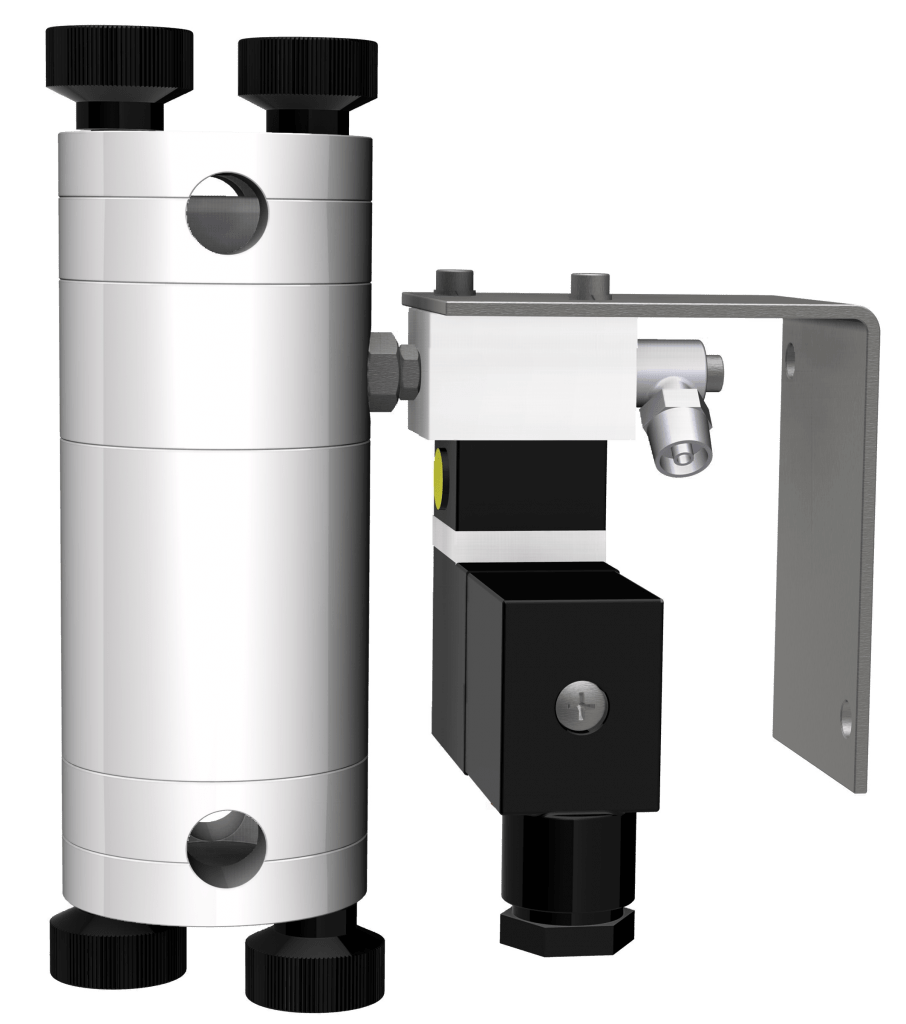

Double valve as changeover. Based on a new demand, the tried-and-tested aluminium valve, in various nominal diameters, was further developed as a shuttle valve. With its essential features remaining the same, the new valve can be controlled with an electro-pneumatic magnet valve in 24 V or 230 V..

- Shuttle valve on each side NC/NO

- Use in sterile zone C/D

- Easy to handle

- Silicone tubing Ø 11.0 ±0.5mm, wall 2.5 ±0.5mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of tube by loosening two knurled nuts

- Min. 10,000 switching cycles with same silicone tubing, without damage to hose

- Compressed air supply 4 - 6 bar

- Squeezing stamp in stainless steel

The Phönix. The reliable SQV® was redesigned and optimised for sterile zone A. Thanks to a refined hinged lid system, the SQV® KV version makes inserting the hose into the insulator with gloves a much more user-friendly process..

- Use in sterile zone A/B

- Easy to handle in insulator

- Silicone tubing dimensions 6-16 ±0.5 mm, wall 2.5-3.2 ±0.25mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of hose by loosening large polygon screw on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to tube

- Compressed air supply 4 - 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

The Phönix. The reliable SQV® was redesigned and optimised for sterile zone A. Thanks to a refined hinged lid system, the SQV® KV version makes inserting the hose into the insulator with gloves a much more user-friendly process.

- Use in sterile zone A/B

- Easy to handle in insulator

- Silicone tubing dimensions 17-20 ±0.5mm, wall 2.5-4.0 ±0.25mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of hose by loosening large polygon screw on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to tube

- Compressed air supply 4 - 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

The Phönix. The reliable SQV® was redesigned and optimised for sterile zone A. Thanks to a refined hinged lid system, the SQV® KV version makes inserting the hose into the insulator with gloves a much more user-friendly process.

- Use in sterile zone A/B

- Easy to handle in insulator

- Silicone tubing dimensions 16-22 ±0.5mm, wall 2.5-5 ±0.25mm

- Standard: peroxide-cured silicone tubing Shore 90° ±5 (others on request)

- Insertion of hose by loosening large polygon screw on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to tube

- Compressed air supply 5 - 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

The Phönix. The reliable SQV® was redesigned and optimised for sterile zone A. Thanks to a refined hinged lid system, the SQV® KV version makes inserting the hose into the insulator with gloves a much more user-friendly process.

- Use in sterile zone A/B

- Easy to handle in insulator

- Silicone tubing dimensions 25.0 ±0.5 mm, wall 3.0 ±0.25mm

- Special: peroxide-cured silicone tubing Shore 90° ±5 (others on request)

- Insertion of hose by loosening large polygon screw on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to tube

- Compressed air supply 5 - 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

SQV® tubing pinch valves

Do you need a flow breaker for silicone hoses?

Our tubing pinch valves will win you over with their durability and gentle squeezing of silicone hoses.

Tech. Docs: tube pinch valve type SQV 84-20 Alu

Tech. Docs: tube pinch valve type SQV 96-2x11 Alu

Tech. Docs: tube pinch valve type SQV 11-G18 AVe KV Stahl

Tech. Docs: tube pinch valve type SQV 21-G18 AVe KV Stahl

Tech. Docs: tube pinch valve type SQV 32-G18 AVe KV Stahl

Our tubing pinch valves will win you over with their durability and gentle squeezing of silicone hoses.

PDF download

Tech. Doku: tube pinch valve type SQV 83-15 aluTech. Docs: tube pinch valve type SQV 84-20 Alu

Tech. Docs: tube pinch valve type SQV 96-2x11 Alu

Tech. Docs: tube pinch valve type SQV 11-G18 AVe KV Stahl

Tech. Docs: tube pinch valve type SQV 21-G18 AVe KV Stahl

Tech. Docs: tube pinch valve type SQV 32-G18 AVe KV Stahl

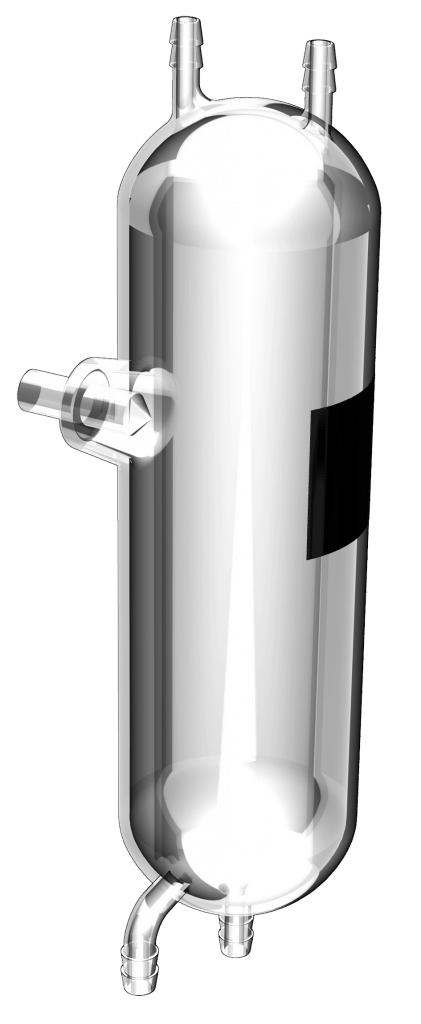

Glass feed vessels

Are you looking for a feed vessel for the sterile filling?

Standard or customized Aquasant glass vessels with filling or limit value measurement control.

Link to glass vessels...

Tech. Doku: Glasgefäss Typ GF26

Tech. Doku: Glasgefäss Typ GF26F

Tech. Doku: Glasgefäss Typ GV1000

Standard or customized Aquasant glass vessels with filling or limit value measurement control.

Link to glass vessels...

PDF download

Prospekt: GLASGEFÄSSE GF*Tech. Doku: Glasgefäss Typ GF26

Tech. Doku: Glasgefäss Typ GF26F

Tech. Doku: Glasgefäss Typ GV1000

Liquid level control unit AS88-6-2010

Are you looking for a feed vessel with self-reliant, compact regulation?

Via hose tubing valves the Liquid Level Control Unit measures, navigates and regulates the filling level within the glass feed vessel in one go.

Tech. Doku: Kompaktgerät

Via hose tubing valves the Liquid Level Control Unit measures, navigates and regulates the filling level within the glass feed vessel in one go.

PDF download

Prospekt: KompaktgerätTech. Doku: Kompaktgerät

Complete monitoring LLCU

Are you looking for a feed vessel with self-reliant, compact regulation?

Via hose tubing valves the Liquid Level Control Unit measures, navigates and regulates the filling level within the glass feed vessel in one go.

Tech. Doku: Niveaukontrollsystem Typ LLCU

Tech. Doku: Schlauchleermelder Typ SLS

Via hose tubing valves the Liquid Level Control Unit measures, navigates and regulates the filling level within the glass feed vessel in one go.

PDF download

Prospekt: Niveaukontrollsystem Typ LLCUTech. Doku: Niveaukontrollsystem Typ LLCU

Tech. Doku: Schlauchleermelder Typ SLS

SQV® service appointment

The hose tubing valves are very robust and wear-resistant. After 1,000,000 switching cycles , the SQVs should be serviced.

The service comprises:

Replacement of closing springs

Replacement of lip seals

Cleaning and re-greasing

Send us your hose tubing valve to be serviced

More information about this service»

The service comprises:

Replacement of closing springs

Replacement of lip seals

Cleaning and re-greasing

Send us your hose tubing valve to be serviced

More information about this service»

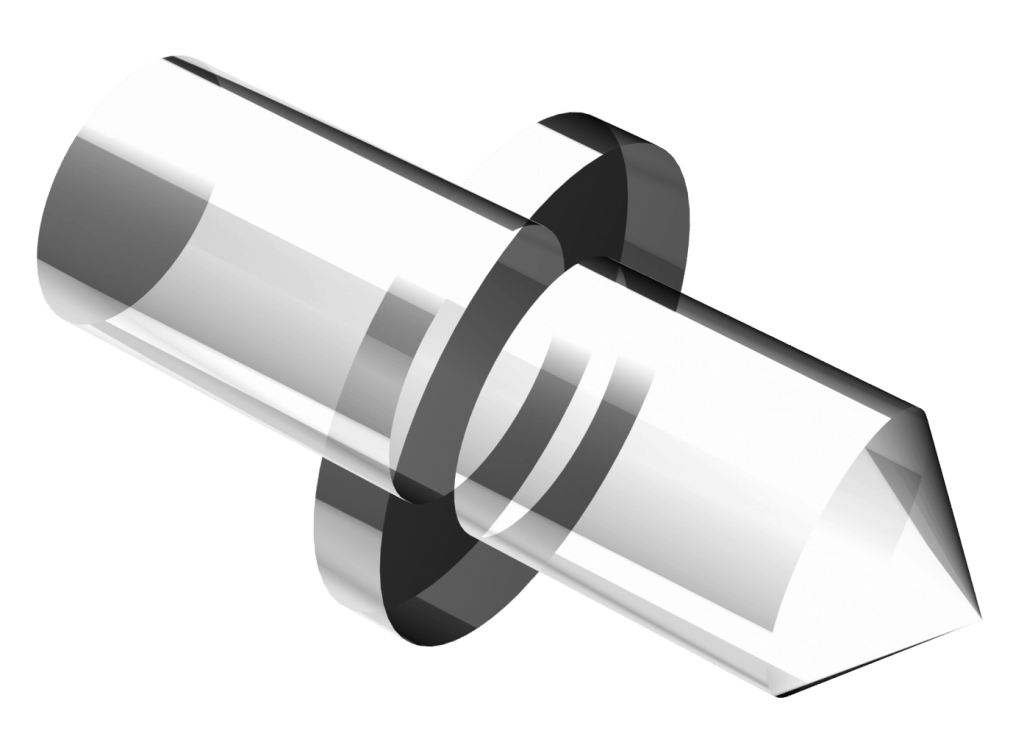

G-FS26

Glass sensor tip

for the AF26 el. optical sensor installed in steel vessels

for the level control of the inlet.

- This is the 1st item

- This is the 2nd item

G-FS26

Exposure glass vessel

for the AF26 el. optical sensor installed in glass vessel

- This is the 1st item

- This is the 2nd item

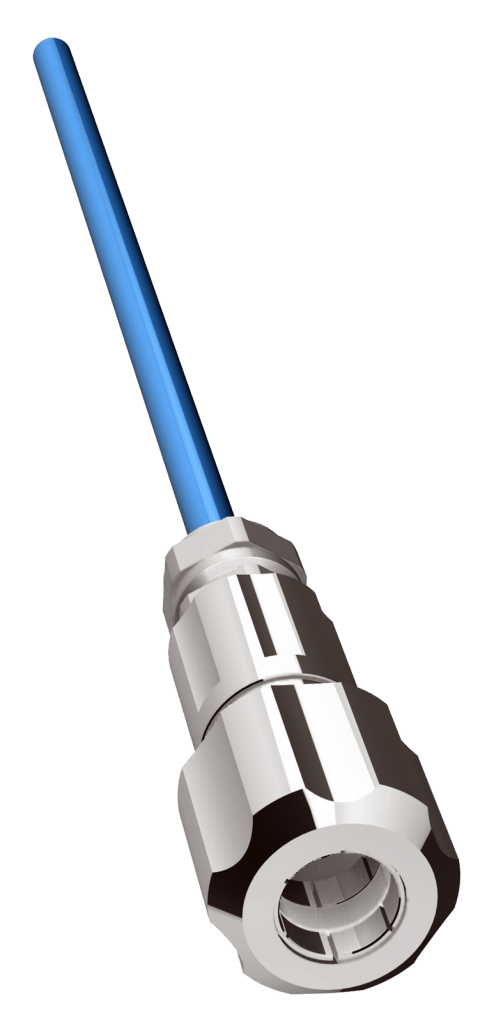

AF26

El. opt. Sensor

for the AF26 el. optical sensor installed in glass vessel

- This is the 1st item

- This is the 2nd item