The full/empty detector monitors all your powders statically or dynamically. Spatial measuring behaviour guarantees reliable measuring of all products.

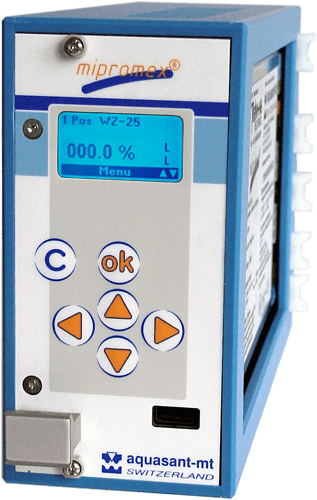

mipromex – the safety switch

The limit value evaluation unit monitors and provides alerts

Guaranteed powder detection in the case of various products different in nature and with electrically conductive and dielectric properties is achieved by means of dynamic measured value processing and three-dimensional measuring behaviour.

Powder point level

Why customers rely on aquasant® level switch powder measurement technology

- Simple commissioning

- Limit value with dynamic measured value processing

- Freely definable static limit value in the measurement range

- Sum measurement signal instead of frequency monitoring (tuning fork)

- Point level or level measurement of low polarity powder

- Contamination-tolerant measuring

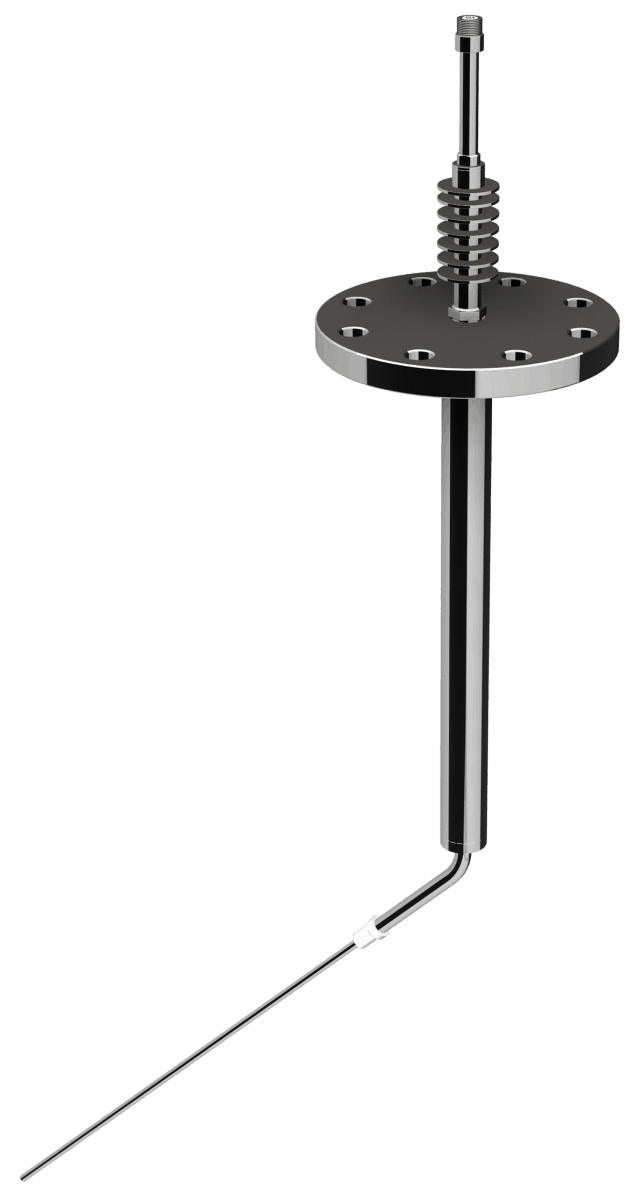

- Two measurement areas in the serial “single rod” design

- Protected against electrostatic charge

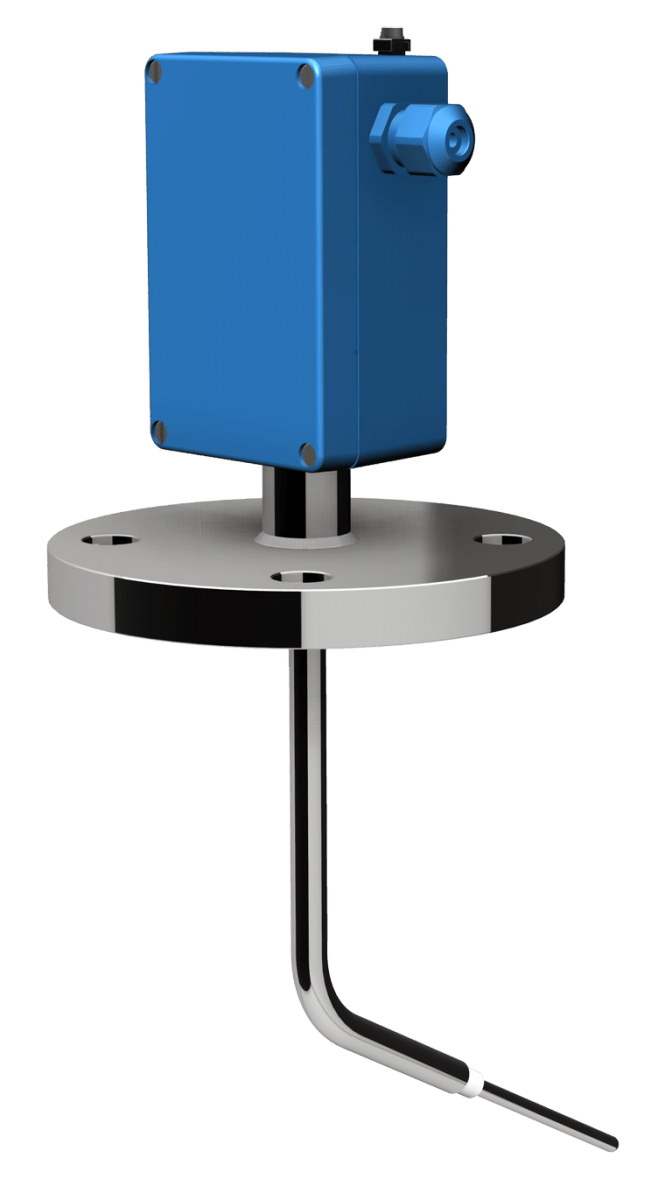

- Curved probes for special installation

- Level measurement in fluidised Aerosil silos

Measuring system

The MLS limit switch can be used for foam detection, for liquids, or for measuring powder levels. The first and second measurement circuits have the same functionality. The evaluation electronics not only serve as a feed unit in the 2-wire technology, but also house the data processing intelligence.

The benefit for you: high economic efficiency and investment security due to the long service life.

Easy fault visualisation, fault notifications on 2nd relay output, if selected

Limit values on the active measurement range length can be freely parameterised

With 1 or 2 measuring inputs

Limit value simulation

plug & process

Ex version: Gas II (2) G [Ex ia Gb] IIC EMC STS 024 CE ****

More information on MLS»

The benefit for you: high economic efficiency and investment security due to the long service life.

Ex version: Gas II (2) G [Ex ia Gb] IIC EMC STS 024 CE ****

More information on MLS»

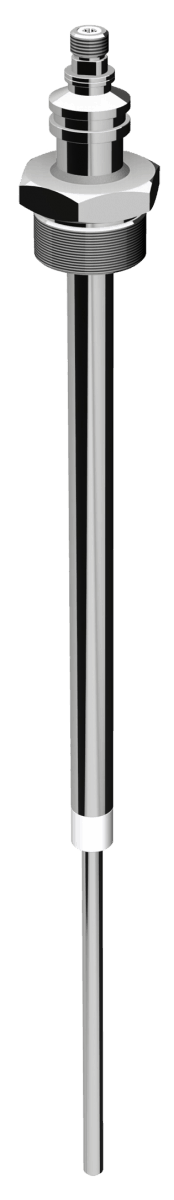

The standardised bar probes are configured according to the process conditions and the media used in a customer-specific way. In contrast to the float system, the probe technology is density-independent and does not require maintenance.

Materialisation: Stainless steel, Hastelloy®, full PTFE designs

Contamination in the inactive area and organic residues on the measuring electrode are negligible

Designs also for extreme process conditions with temperatures of up to max. 300°C and pressure up to 1000 bar

Despite the aqueous phase on top (phase reversal), we achieve precise measurement results

The bar probes are specially designed according to the process conditions, the application, the industry as well as the media to be used. Whether in the chemical, pharmaceutical or hard petrochemical industry, the right probe technology is at your disposal.

The standardised bar probes are configured according to process conditions and the media used in a customer-specific way. In contrast to the tuning fork system, the probe technology is product-specific and thus can be used universally.

Materialisation: Stainless steel, Hastelloy®, full PTFE designs

Contamination in the inactive area and organic residues on the measuring electrode are negligible

400°C and pressure up to 1000 bar

Quick measurement: 300 ms guarantees reliable detection

The standardised bar probes are configured according to process conditions and the media used in a customer-specific way. In contrast to the tuning fork system, the probe technology is product-specific and thus can be used universally.

limit value powder probe STM

Documentation

Limit switch probes for low to high polarity powders

The high-resolution impedance measuring principle in the MTI measuring electronics with electrostatic protection can record all powder types digitally as a limit value. A wide range of probes allows for all types of installation. Through spatial measuring behaviour and the probe technology there is a high signal-to-noise ratio in the case of contamination at the measuring electrodes. This results in the perfect detection of different types of powder. The mipromex MLS evaluation unit is equipped with a graphic display for visualising the powder level and setting the limit values.

Tech Docs: Limit value bar probe type SRM

Tech Docs: Limit value bar probe type STM

Tech Docs: Limit Switch evaluation unit type MLS

The high-resolution impedance measuring principle in the MTI measuring electronics with electrostatic protection can record all powder types digitally as a limit value. A wide range of probes allows for all types of installation. Through spatial measuring behaviour and the probe technology there is a high signal-to-noise ratio in the case of contamination at the measuring electrodes. This results in the perfect detection of different types of powder. The mipromex MLS evaluation unit is equipped with a graphic display for visualising the powder level and setting the limit values.

PDF download

Brochure: Powder detectionTech Docs: Limit value bar probe type SRM

Tech Docs: Limit value bar probe type STM

Tech Docs: Limit Switch evaluation unit type MLS