Continuous separation layer measurement in the decanter

Separation layer measurement of non-mixable fluids with emulsion, phase reverse, as generated during extraction or after a chemical process, is our strength. We control the phase level with the impedance measurement despite severe contamination, extremely small density differences or layers of mulch.

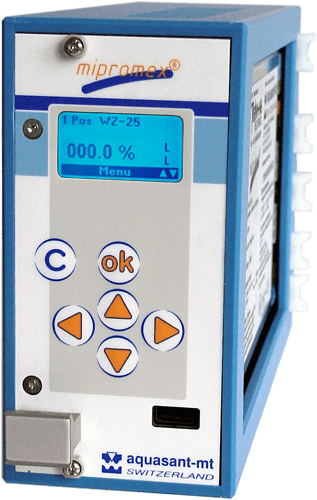

mipromex – the multi-talent

The separation layer unit monitors, detects and controls the separation layer

The high-resolution separation layer measurement system continuously monitors the separation layer in decanters, mixer-settlers and columns or in pipelines. Our customers are impressed by the universal use, high measurement precision and easy commissioning. A reliable measurement of all products is guaranteed by applying the impedance measuring principle. The self-monitoring measuring and control unit ensures reliable phase monitoring.

Fluid/fluid phase separation

Why customers rely on aquasant® separation layer measuring technology

- Sum measurement signal instead of runtime measurement

- Density independence

- Separation layer measurement of two organic phases

- Measurement through glass instruments without touching the product

- Measurement without sensitivity to contamination

- Serial design of two measurement ranges in “single rod”

- Desalination systems under high voltage (50kV)

- Lab probes in extremely small designs

- Curved probes for special installation

The multi-talented MIQ can be used from the separation layer level measurement to batch separation. With the option of a 2nd measurement circuit, the phase monitoring system, the fill level or the separation behaviour can be measured. The evaluation electronics not only serve as a feed unit in the 2-wire technology, it also houses the data processing intelligence.

Your benefit: High economic efficiency and investment security due to the long service life.

Universally usable, reduced storage costs

With one or two measuring inputs

Continuous separation layer monitoring

Phase monitoring for safety-optimised separation

Combination with level measuring of the upper phase

Ex version: Gas II (2) G [Ex ia Gb] IIC / Dust II (2) D [Ex ia Db] IIIC / Gas (2) D [Ex d ia] IIC

EMC STS 024 CE ****

Your benefit: High economic efficiency and investment security due to the long service life.

Ex version: Gas II (2) G [Ex ia Gb] IIC / Dust II (2) D [Ex ia Db] IIIC / Gas (2) D [Ex d ia] IIC

EMC STS 024 CE ****

The soloist, MIL, focuses the functionality on continuous separation layer measuring. The evaluation electronics not only serve as a feed unit in the 2-wire technology, it also houses the data processing intelligence.

Your benefit: Maintenance-free and cost-effective due to long service life.

Continuous separation layer monitoring

With one measuring input

Easy fault visualisation, fault notifications on analog output

mA output and limit value simulation

Ex version: Gas II (2) G [Ex ia Gb] IIC / Dust II (2) D [Ex ia Db] IIIC / Gas (2) D [Ex d ia] IIC

EMC STS 024 CE ****

Your benefit: Maintenance-free and cost-effective due to long service life.

Ex version: Gas II (2) G [Ex ia Gb] IIC / Dust II (2) D [Ex ia Db] IIIC / Gas (2) D [Ex d ia] IIC

EMC STS 024 CE ****

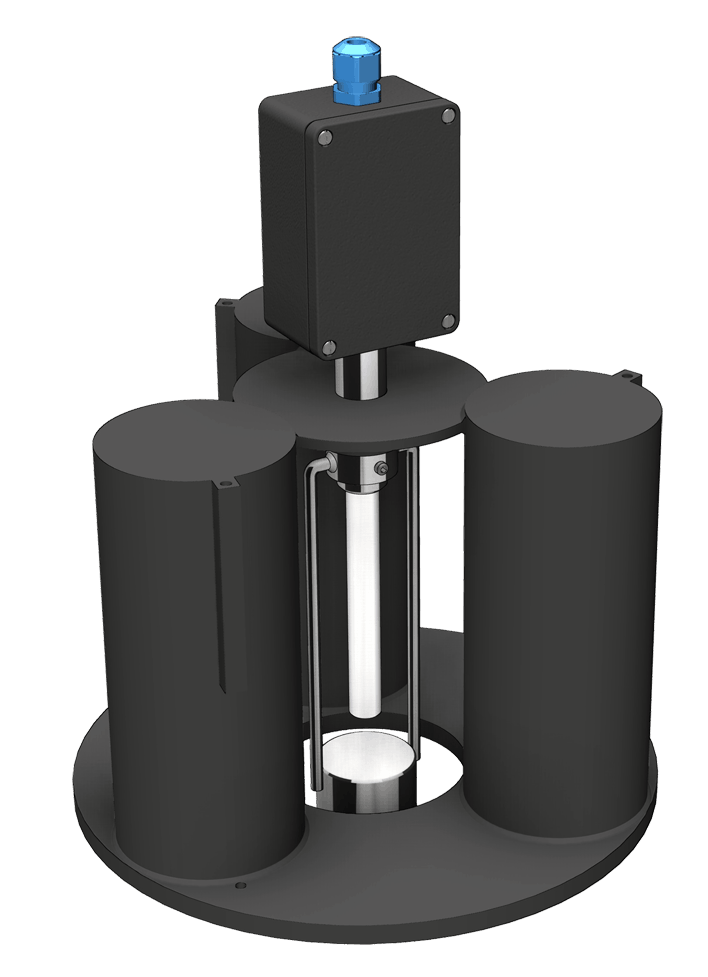

The QTI 820 K measuring unit works according to the same principle as the mipromex separation layer measuring unit. The 2nd channel allows for a phase to be measured and compensated even if this phase’s properties change. The evaluation electronics not only serve as a feed unit in the 2-wire technology, it also houses the data processing intelligence.

Product compensation for variable phases

QTI 820 K can only be used for continuous separation layer level measuring

With two measuring inputs

Fault visualisation, fault notifications on relay output

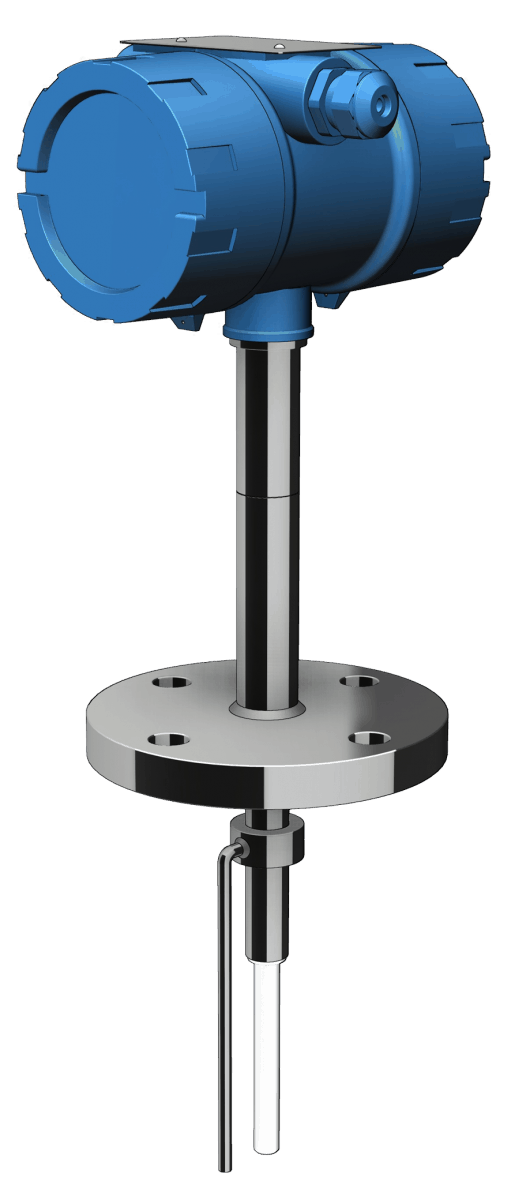

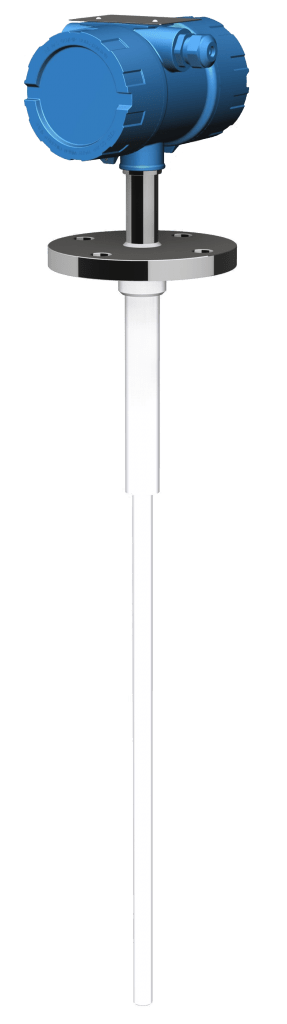

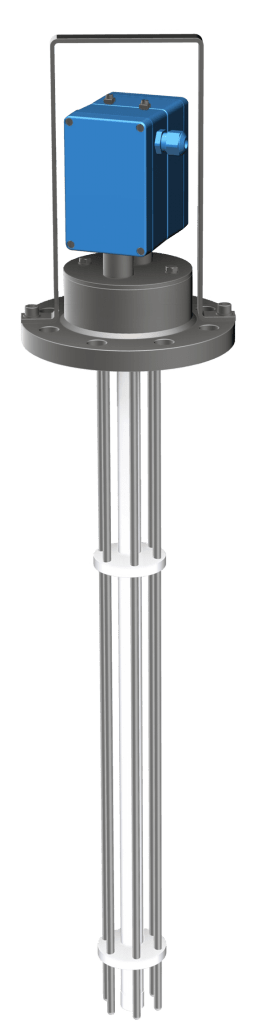

The standardised bar probes are configured to customer-specific process conditions and the media used and are maintenance-free. In contrast to the conventional measuring systems, the aquasant probe technology does not require any moving parts and is independent of dielectricity constant, density and organic residues.

Materialisation in accordance with requirement (e.g. stainless steel, Hastelloy®, full PTFE designs)

Organic contamination or residues are negligible

Designs for extreme process conditions with temperatures of up to max. 300°C and pressure up to 1000 bar

Reliable measurement even for the above aqueous phase (phase reversal)

With decades of experience in the field of phase separations, we face every challenge with the auto-dynamic batch separation.

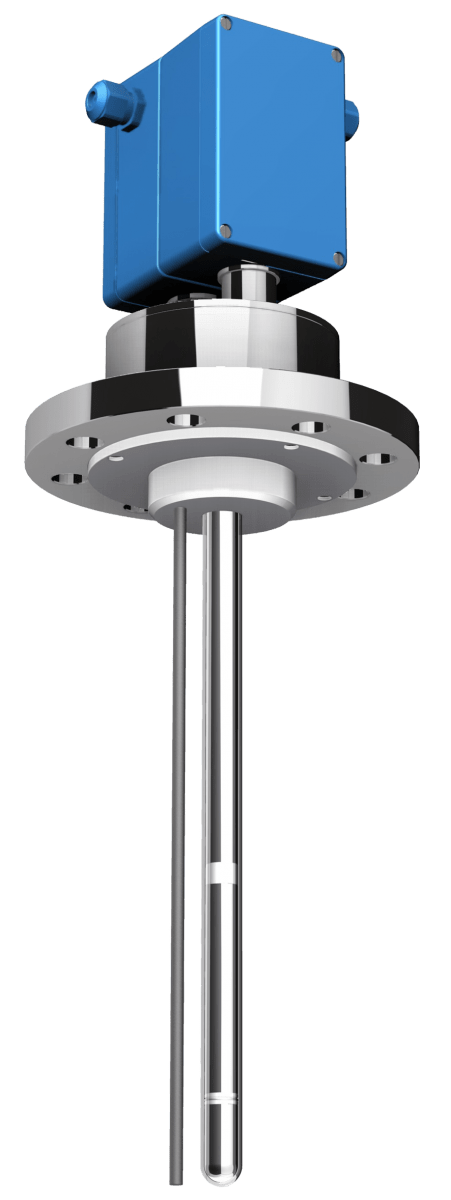

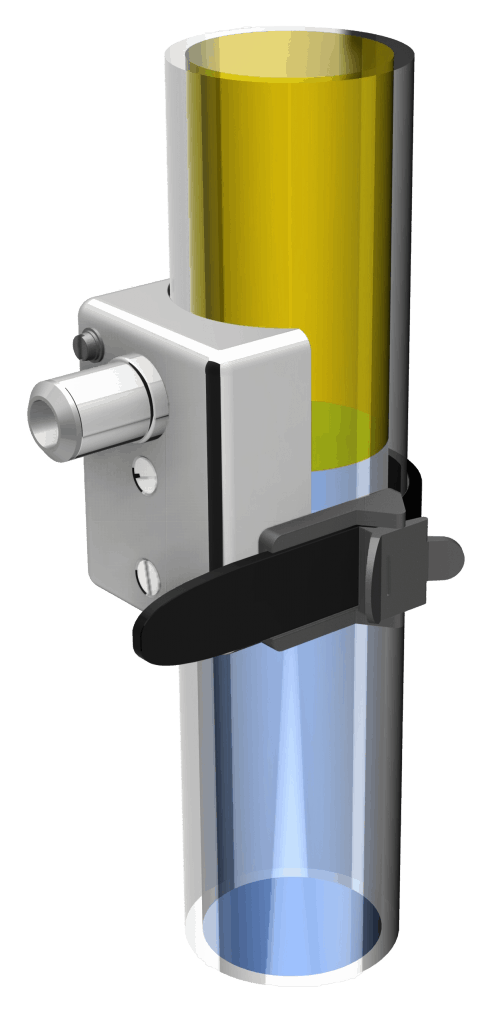

Our unique TSS80 tube probes are specifically configured in accordance with your process conditions. All ring probes are parameterised at the factory and do not require commissioning: simply plug & process.

Our unique TSS80 tube probes are specifically configured in accordance with your process conditions. All ring probes are parameterised at the factory and do not require commissioning: simply plug & process.

Documentation

Continuous interface measurement with mipromex MIQ or MIL with bar probe STM according to customer specification

Tech Docs: Interface bar probe type STM (316L)

Tech Docs: Interface bar probe type STMd (316L)

Tech Docs: Interface bar probe type (full-PTFE)

Tech Docs: Interface clamp probe for Glass tube type FRGL80/60 SE R U EF GR60

Tech. Docs: Interface evaluation unit mipromex type MIQ Multitalent

Tech Docs: Interface evaluation unit mipromex type MIL Solist

Tech Docs: Interface bar probe type STM 2TN

Tech Docs: Interface evaluation unit type QTI 820

PDF download

Brochure: Interface level measurementTech Docs: Interface bar probe type STM (316L)

Tech Docs: Interface bar probe type STMd (316L)

Tech Docs: Interface bar probe type (full-PTFE)

Tech Docs: Interface clamp probe for Glass tube type FRGL80/60 SE R U EF GR60

Tech. Docs: Interface evaluation unit mipromex type MIQ Multitalent

Tech Docs: Interface evaluation unit mipromex type MIL Solist

Tech Docs: Interface bar probe type STM 2TN

Tech Docs: Interface evaluation unit type QTI 820

Trennschicht-Sonde im Mixer Settler